After long CAD development based on 3D scans of the OEM subframe, tests with CAD FEA (finite element method) and practical tests, you can now buy branded subframes for the rear axle of your Audi/VW/SEAT/Skoda based on the MQB platform with Haldex. Vehicle list below.

By using the same T45 tubes as in WRC cars, our subframes offer increased rigidity, weight reduction and more precise handling. All factory parts can be bolted to this unit and no further modifications are required.

This version is intended for vehicles whose chassis is to be additionally stiffened by a rear axle cross member reinforcement. Most vehicles are used on racetracks. For vehicles used on drag strips, we offer the WAS-561 version.

advantages (for more information, see the bottom of the page):

- 13.6 kg. This is 4.5 kg less than the OEM steel MQB subframe and 5 kg less than the OEM steel PQ35 subframe (TT 8J, A3 8P).

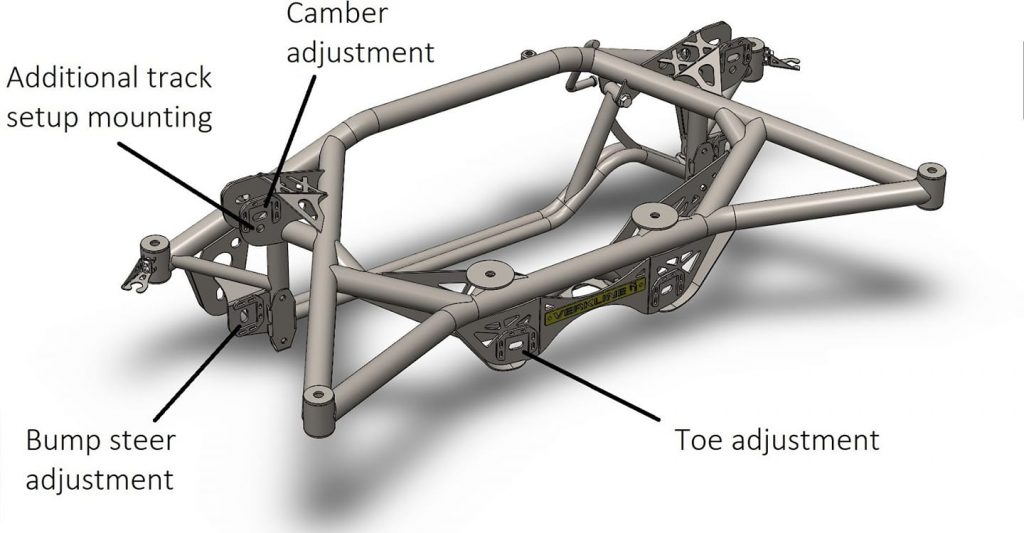

- Possibility to adjust camber, toe and bump steer.

- Additional toe adjustment for upper control arm - provides better camber reinforcement and roll center position (requires adjustable control arm to maintain camber setting).

- A subframe mounting position prevents the subframe from moving under the vehicle. No subframe locking kit/rear axle inserts made of billet aluminum required (weight saving).

- Increases chassis stiffness for improved handling.

- Additional rear axle cross member. The reinforcement, similar to the Audi Sport rear axle cross member, increases rigidity. This leads to even better vehicle handling at high speeds and increased lateral forces.

More pictures and additional information can be found below.

Properties:

- Better access to the underbody and wishbone replacement without removing the subframe.

- T45 pipes (BS4T45 to BS4T100) imported from the UK and S355 sheet metal.

- All components TIG-welded.

- Supplied painted black (powder-coated) or on special order (50 euros) in any RAL color.

- Can be used with OEM control arms or our adjustable control arms.

- Mounted on the OEM body, no further modifications are required to mount the subframe.

- Including brackets for two OEM xenon rear light sensors.

- Can be used with exhaust systems up to 4 inches with OEM center positioning.

- No subframe inserts or our aluminum subframe bushes required, as the subframe is firmly attached to the body.

Scope of delivery:

- Rear subframe, powder-coated - WAS-564

- Reinforcing strut for the lower rear axle cross member

- 1x set of adjustable 3 mm metal control arm positioning washers for -5, -4, -3, -2, -1, 0, 1, 2, 3, 4 and 5 mm positioning.

- Printed installation instructions

Compatible vehicles with PQ35 and MQB platform (type numbers in brackets):

- Audi A3/S3 (8Y) all-wheel drive (2022)

- Audi A3/S3 (8P & 8V & 8VFL (2012-2021) with Haldex

- Audi RS3 (8V & 8FV (2013))

- Audi TT/TTS (8J & 8S (2006) with Haldex

- Audi TTRS (8J & 8S (2009))

- Audi Q2 (2017)

- Audi Q3 / RSQ3 (F3 (2018))

- SEAT León Mk3 (5F) (2006-2013) with Haldex

- VW Golf Mk5 Mk6 Mk7 Mk8 (2003) with Haldex (all-wheel drive)

Note: Not compatible with Audi RS3 8P and VW Golf R32. The battery is located under the vehicle behind the rear subframe. Our subframe can be used, but the battery compartment must be relocated.

T45 is a unique seamless carbon-based steel tube that is used in many applications in various industries. It is stronger than the Co-Mo 4130 tube also used in motorsport. It is commonly used in aerospace for equipment such as pilot seats and crew seats as it can withstand high G-forces without breaking or splintering. The material is carbon-manganese based and meets the full aerospace specifications of British Standards.

Properties:

- Tensile strength: 700-900 MPa,

- 0.2 % yield strength: at least 620 MPa

- Hardness test: 201 min - 262 max. HB or 210 min - 275 max. HV

Replaced:

- 5Q0505235E

- 5Q0505235J

- ZAW071151DDSP (rear axle cross member reinforcement)

Note: Only available for off-road, racetrack and racing applications. The installation of the subframe can lead to an increase in noise, vibration and harshness (NVH) in the vehicle. Our tests with a standard VW Golf 7R showed a minimal increase in NVH values at idle. We strongly recommend having the subframe fitted by a qualified and experienced workshop.

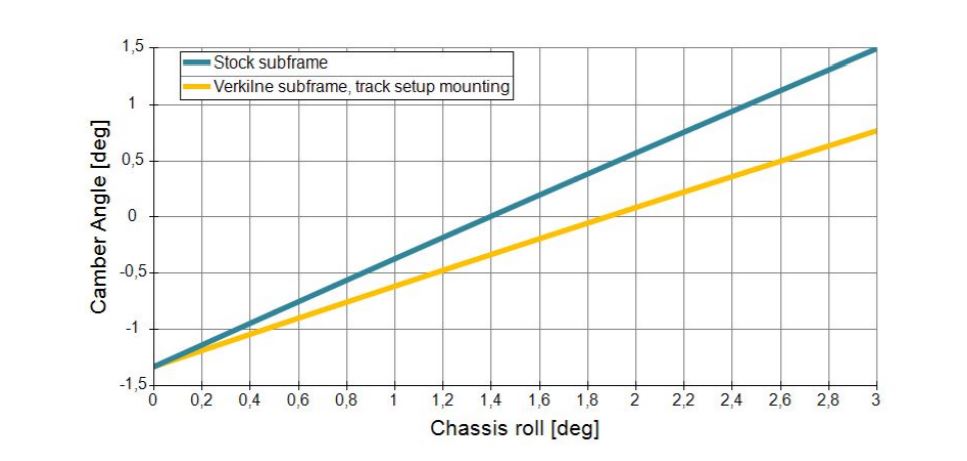

Additional technical information: To improve the cornering behavior of a standard vehicle, one of the first measures is to reduce the ground clearance. Unfortunately, this not only lowers the center of gravity, but also the roll point, which can have a negative effect on responsiveness. To prevent this, our new subframe has an additional, toe-in mounting for the upper wishbone. As well as correcting the roll point, this also contributes to camber reinforcement (changing the camber angle within the suspension travel). Original MQB/PQ35 cars have almost none of this to stay within the same small, non-aggressive camber for the tires, whether you're driving the car solo or fully loaded with an extra several hundred pounds. In circuit racing, the priority is to optimize camber gain to reduce positive camber in corners for better grip, and that's exactly what our additional suspension provides.

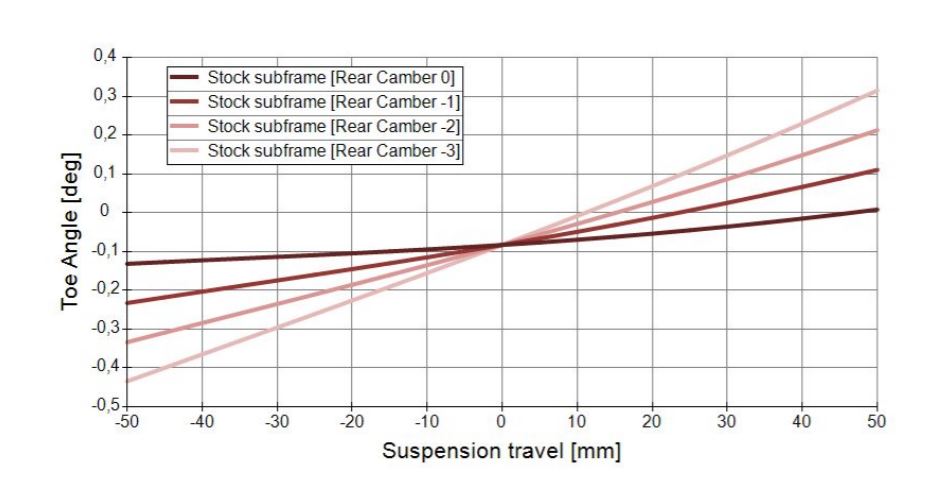

The next disadvantage of the standard rear suspension of the MQB/PQ35 platform in racing is the enormous influence of the camber angle on the bump steer function (change of the toe angle within the suspension travel).

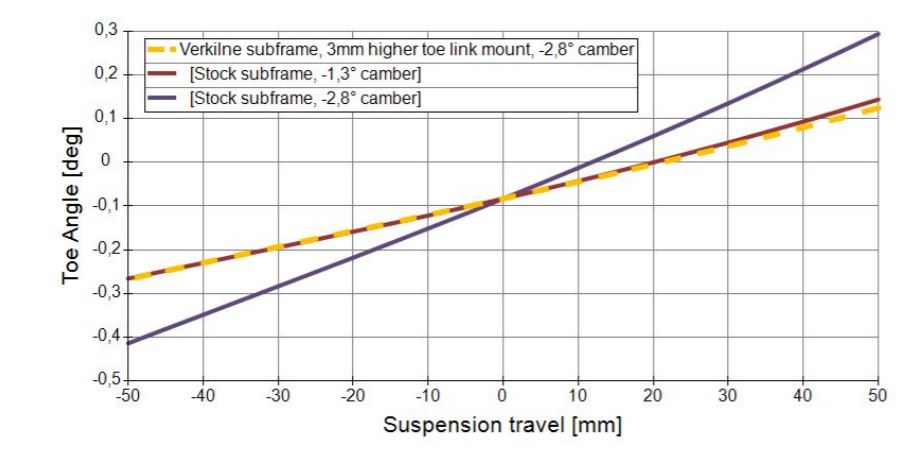

To facilitate this, we have added a vertical slot to the tie rod bracket to allow for bump steer adjustment. To compensate for the effect of every 0.5° change in camber on the bump steer setting, the tie rod bracket must be mounted 1 mm higher. For example, if you want to increase your rear camber from -1.3° to -2.8° and do not want to change the bump steer setting, you should mount your tie rod bracket 3 mm higher. We supply special offset washers with our subframes that enable quick and precise adjustment by 1 mm.

Unless otherwise indicated, all articles and services are racing articles without guarantee / warranty and without STVO approval.

The same applies to modifications made to the vehicle. The performance values offered are average values on ARAL 102 OKTAN fuel, which may deviate accordingly due to inferior fuel or wear on the vehicle.

No acceleration times are guaranteed. Subsequent misfueling may cause damage to the vehicle. No guarantee / warranty is assumed for this!

HPerformance does not assume any mobility warranty / costs for the duration of the conversion or any resulting delays.

Scheduled appointment periods are not binding and may vary.

All services are special and custom-made products that are excluded from the statutory right of return.

No warranty is assumed for products that are not installed in a specialist workshop by trained specialist personnel.

Work on motor vehicles may only be carried out by trained specialists. In addition to product malfunctions, installation errors can also lead to dangerous technical and possibly legal consequences for the vehicle.

Therefore, please have all conversions carried out by a specialist vehicle workshop of the guild.

If no instructions for installing a product are available for download in the online store, these are not available

- No installation advice / installation instructions are provided by telephone.

If vehicles have already been modified beforehand, additional costs may be incurred. Please note that our TÜV-approved/registrable products are not necessarily compatible with products from other manufacturers ! Please check in advance whether your already installed hardware parts, which are not from HPerformance, are TÜV-compliant with our products!

Discoloration occurs on the silencers, pipe and tailpipe of all exhaust system components during operation. These are material-related changes that are not covered by the warranty/guarantee of the item and have no negative effect on the use or technical properties of the item.